Key Takeaways for Smarter Construction

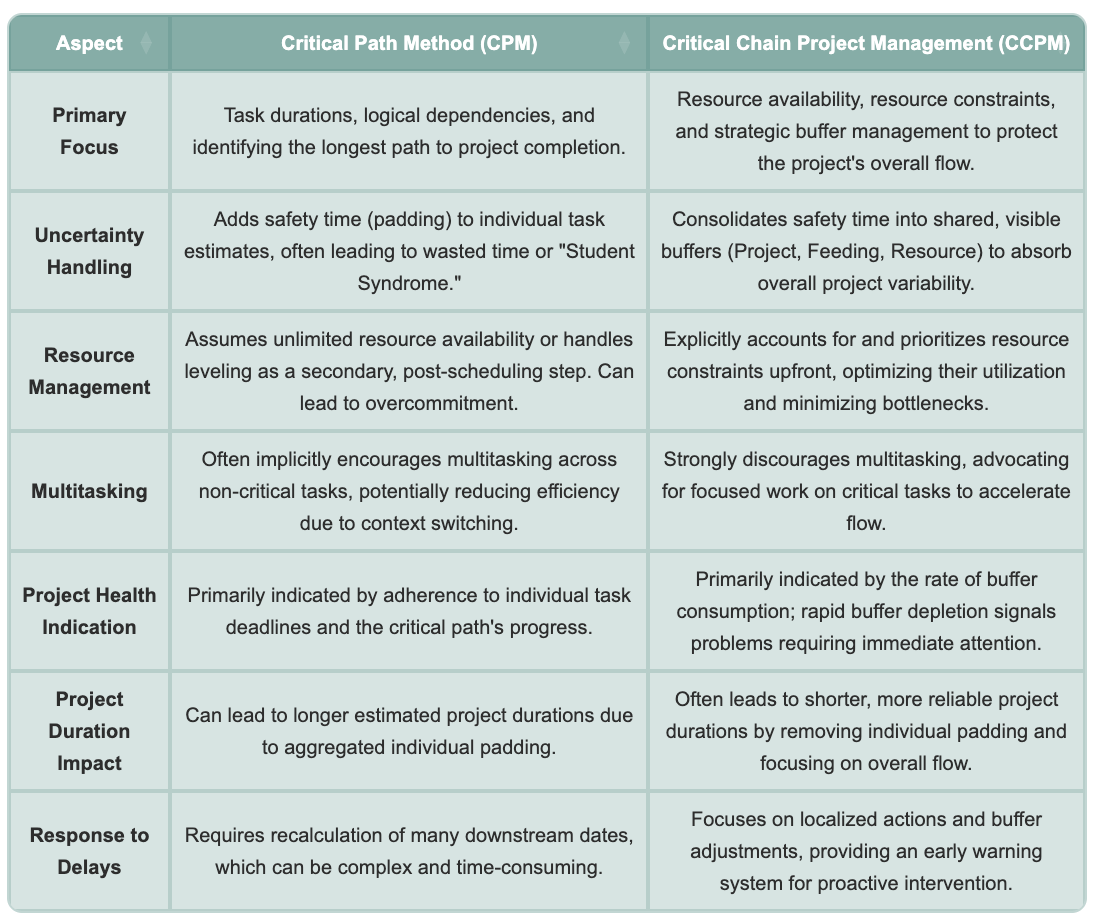

- CPM (Critical Path Method) identifies the longest sequence of tasks for project completion but often falls short in construction due to its assumption of unlimited resources and perfect conditions, leading to padded schedules and reactive management.

- CCPM (Critical Chain Project Management) is an adaptive approach that prioritizes resource availability and strategically places shared buffers, making it more resilient to the common uncertainties in construction like material delays, weather, and labor availability.

- Integrating Archdesk empowers CCPM by providing real-time visibility into project health, facilitating efficient resource leveling, and offering comprehensive tools for tracking buffer consumption and managing project finances, leading to better on-time completion and cost control.

The Project Management Crossroads: CPM vs. CCPM

For decades, construction professionals have relied on various methods to keep projects on track. The Critical Path Method (CPM) has been a go-to for many, offering a clear way to map out tasks and identify the longest sequence dictating a project's timeline. Yet, construction is a dynamic field, constantly throwing curveballs – unexpected weather, material shortages, or a key subcontractor juggling multiple jobs. These real-world challenges often expose the limitations of traditional CPM. This is where Critical Chain Project Management (CCPM) offers a more robust and realistic way to manage projects, particularly within the unpredictable landscape of construction.

CPM: The Traditional Blueprint

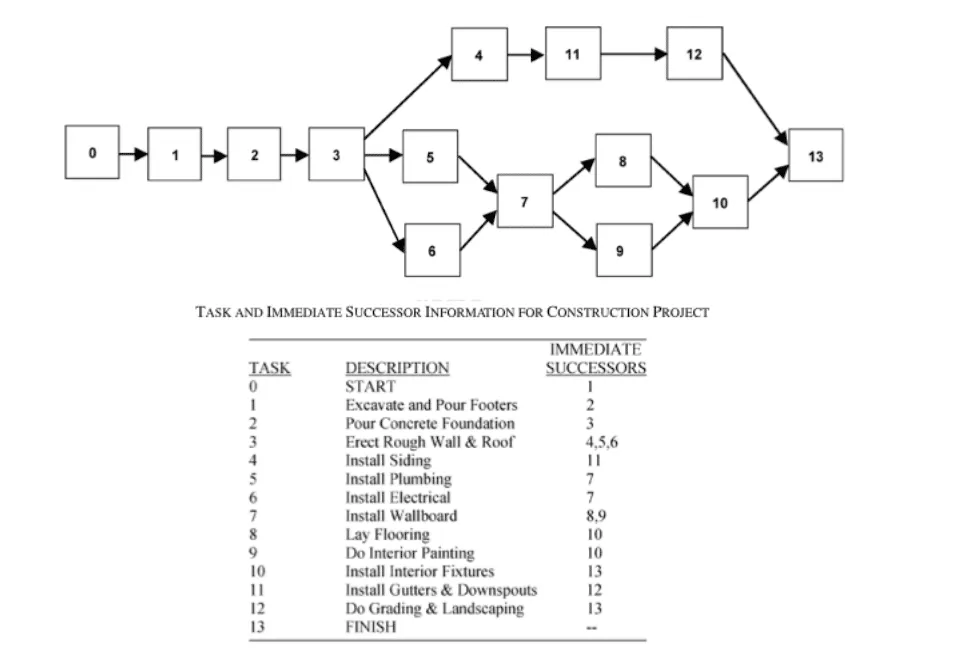

CPM is like creating a rigid roadmap for your project. You break down the entire project into individual tasks, figure out which tasks depend on others, and estimate how long each one will take. The critical path is then the longest series of these interdependent tasks. If any task on this path experiences a delay, the entire project timeline gets pushed back.

The strength of CPM lies in its clarity. It gives a single, earliest possible completion date and highlights the tasks that absolutely must stay on schedule. This method works well for projects where conditions are highly predictable, resources are readily available, and uncertainties are minimal. However, construction rarely fits this ideal scenario. Often, individual task estimates are padded with extra time to account for potential issues, a practice that can inflate overall project durations without truly addressing underlying risks. This "safety time" often goes to waste due to human tendencies like Parkinson's Law (work expanding to fill the time available) or the Student Syndrome (procrastinating until the last minute).

Visualizing a typical Critical Path Method diagram.

CCPM: The Adaptive Approach

CCPM, developed by Eliyahu M. Goldratt as part of his Theory of Constraints, takes a different view. While it builds on the concept of a critical path, its primary focus shifts to managing resources and the inherent uncertainties of a project. Instead of padding individual tasks, CCPM consolidates this safety time into strategically placed "buffers." These buffers act as collective safety nets for the entire project, designed to absorb delays without jeopardizing the final completion date.

The "critical chain" in CCPM is more than just the longest sequence of tasks; it's the longest path of dependent tasks that also considers resource availability and limitations. This means the critical chain might look different from a simple critical path because it factors in that your most skilled electrician can't be in two places at once, or that a specialized piece of equipment has limited availability. By identifying and managing these resource constraints upfront, CCPM aims to create more realistic and achievable schedules.

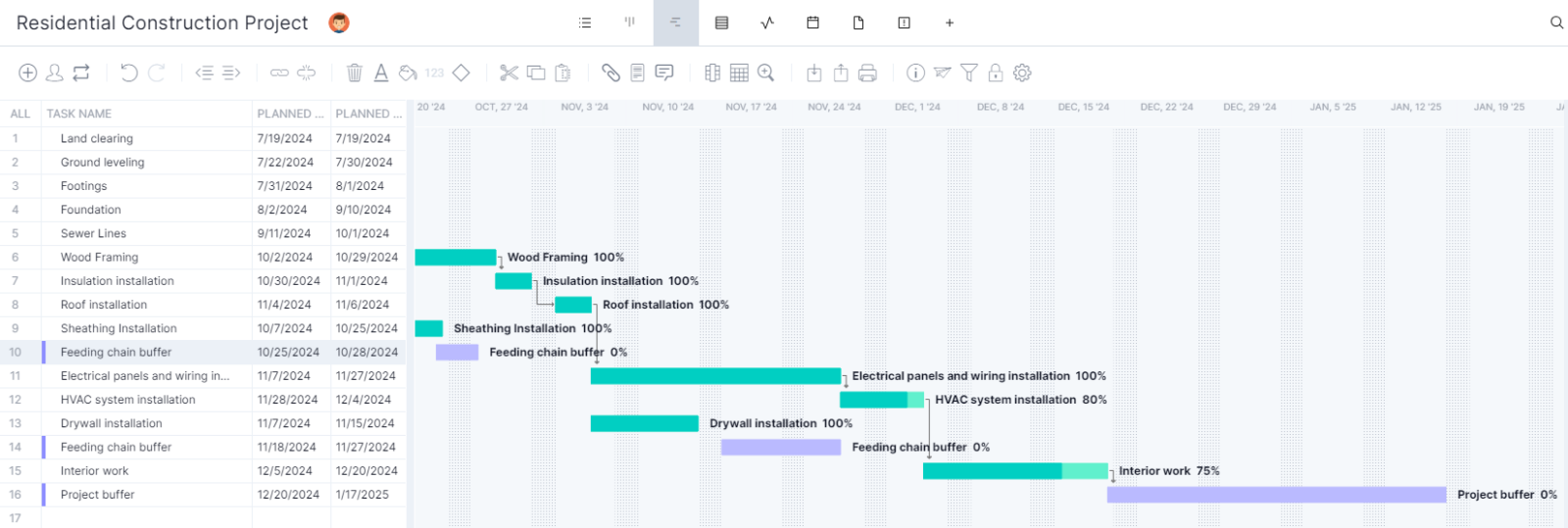

An example of a Critical Chain diagram, showing the placement of buffers.

Unveiling the Critical Chain Concept

The core idea behind the critical chain is acknowledging that projects are not just sequences of tasks, but also intricate webs of resource dependencies. In a construction setting, this is particularly true. A delayed concrete pour impacts not just the next task in sequence, but also the crew waiting for the pour, the equipment needed, and subsequent trades. CCPM proactively identifies these resource bottlenecks and builds the schedule around them.

The Power of Buffers

Buffers are the secret sauce of CCPM. Instead of spreading tiny bits of padding across every task, which often get wasted, CCPM pools this safety time into a few key buffers:

- Project Buffer: Placed at the very end of the critical chain, this buffer protects the overall project completion date from unforeseen delays that occur along the critical path. It's the ultimate safety margin for the entire project.

- Feeding Buffers: These are placed where non-critical task sequences "feed into" the critical chain. Their purpose is to protect the critical chain from delays in these feeder paths, ensuring that the main critical flow isn't disrupted by issues on parallel activities.

- Resource Buffers: While not time buffers in the same way, resource buffers serve as warnings or signals to ensure that critical resources (people, equipment, materials) are ready and available just when they are needed for tasks on the critical chain. This helps prevent costly idle time and ensures smooth transitions.

Monitoring these buffers becomes a central part of project management in CCPM. If a buffer is depleting too quickly, it's an early warning sign that a problem is brewing, allowing project managers to intervene proactively rather than reactively.

Side-by-Side: CPM vs. CCPM in Construction

Let's lay out the fundamental differences between these two project management philosophies. Understanding these distinctions is key to deciding which approach is best suited for the complexities of your next construction endeavor.

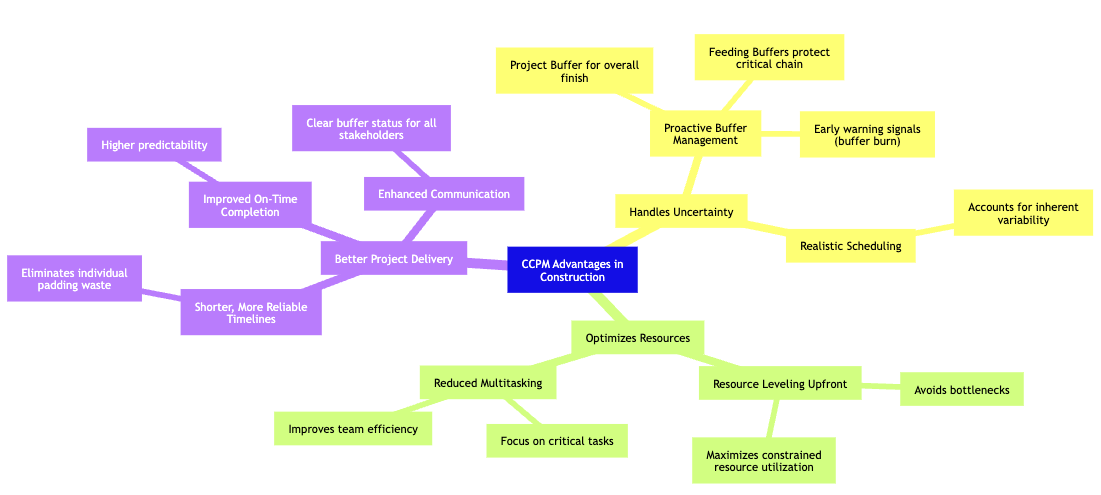

Why CCPM is the Right Tool for Construction's Chaos

Construction projects are inherently complex and prone to unexpected events. Unlike a controlled factory environment, a construction site is subject to external factors like weather, regulatory changes, and the unpredictable availability of specialized labor or materials. This constant flux makes CPM's rigid structure less effective. CCPM, by design, embraces and plans for this uncertainty, making it a natural fit for the construction industry.

Navigating Uncertainty with Strategic Buffers

The strategic use of buffers is CCPM's biggest advantage in construction. Instead of project managers constantly reacting to individual task delays, the buffers provide a visible "safety net" that allows for proactive management. For instance, a residential building project might face delays due to unexpected heavy rain. In a CPM-managed project, this could halt the entire schedule, leading to frantic re-planning. With CCPM, a pre-assigned feeding buffer for site preparation could absorb this weather delay without impacting the start of the next critical task, like foundation pouring. Monitoring the buffer's consumption rate would alert the project manager early, allowing them to adjust resources or accelerate subsequent tasks if needed.

Optimizing Resource Flow: A Construction Imperative

Resource limitations are a constant headache in construction. Whether it's a specific type of crane, a highly skilled foreman, or the availability of specialized subcontractors, resources are rarely unlimited. CPM often assumes resources will be available when needed, leading to unrealistic schedules and resource overcommitment. CCPM, however, explicitly accounts for resource constraints from the outset. It prioritizes the flow of the critical chain, ensuring that the most constrained resources are utilized efficiently and never idle.

Imagine a scenario where the same welding crew is needed for two different critical tasks on two different projects. CPM might optimistically schedule both, leading to inevitable delays on one. CCPM would identify this resource conflict and build the critical chain around the crew's availability, using resource buffers to ensure they are prepared and ready when a critical task demands their attention. This focus on resource leveling significantly reduces bottlenecks and improves overall project execution.

Cultivating Focus: Less Multitasking, More Progress

In many construction environments, teams are often pulled in multiple directions, leading to frequent context switching and reduced productivity. CCPM encourages a "focus first" approach. By clearly defining the critical chain and managing buffers, teams can concentrate on completing one critical task at a time without the pressure of arbitrary individual deadlines or the temptation to jump between incomplete tasks. This single-minded focus can lead to faster task completion times and improved quality of work, as crews aren't constantly shifting their attention and setup.

A mindmap illustrating the various advantages of Critical Chain Project Management in the construction sector.

Archdesk: Your Ally in Critical Chain Management

While CCPM offers a powerful theoretical framework, its true effectiveness comes to life when supported by the right tools. Managing complex schedules, tracking resources, and monitoring buffer consumption manually can be cumbersome. This is where a comprehensive construction management platform like Archdesk becomes an invaluable partner, seamlessly integrating CCPM principles into daily project operations.

Empowering CCPM with Archdesk's Features

Archdesk is a cloud-based solution designed specifically for construction companies, offering a wide array of features that align perfectly with the needs of CCPM. It moves beyond simple task tracking to provide a holistic view of project health, resources, and financials.

Real-Time Visibility and Buffer Tracking

A cornerstone of CCPM is the active monitoring of buffers. Archdesk provides real-time dashboards that can be customized to display key performance indicators, including the status of your project and feeding buffers. Imagine seeing a visual gauge showing how much of a buffer remains (e.g., "70% remaining") or a color-coded warning when a buffer dips below a critical threshold. This immediate feedback allows project managers to understand how quickly buffers are being consumed and to take proactive steps if a problem is developing before it impacts the critical chain.

For example, if the buffer allocated for unexpected delays in material delivery starts to shrink rapidly, Archdesk can send an alert, prompting the project manager to investigate with suppliers or explore alternative options, long before the core construction work is stalled.

Streamlined Resource Allocation

CCPM's strength lies in its explicit focus on resource constraints. Archdesk's robust resource management capabilities enable project managers to allocate personnel, equipment, and even physical space efficiently. Its scheduler allows for visualizing who is assigned to what task, for how long, and when. This helps identify potential resource conflicts early in the planning phase, which is crucial for defining an accurate critical chain. By having a clear picture of resource availability, Archdesk helps prevent overcommitment and ensures that critical resources are deployed precisely when needed for critical chain tasks.

Integrated Financial and Communication Tools

CCPM is not just about time; it's also about cost efficiency. Archdesk's integrated financial management tools, including estimating, quoting, and cost tracking, allow for a clear understanding of the financial implications of project progress and buffer consumption. If a buffer is being used up quickly, it might have cost implications that Archdesk can help monitor.

Furthermore, effective communication is vital in any project. Archdesk's RFI management and centralized communication features ensure that information flows smoothly, reducing misunderstandings and delays that could impact the critical chain. This prevents information bottlenecks and keeps all stakeholders aligned on the project's most critical paths and resource needs.

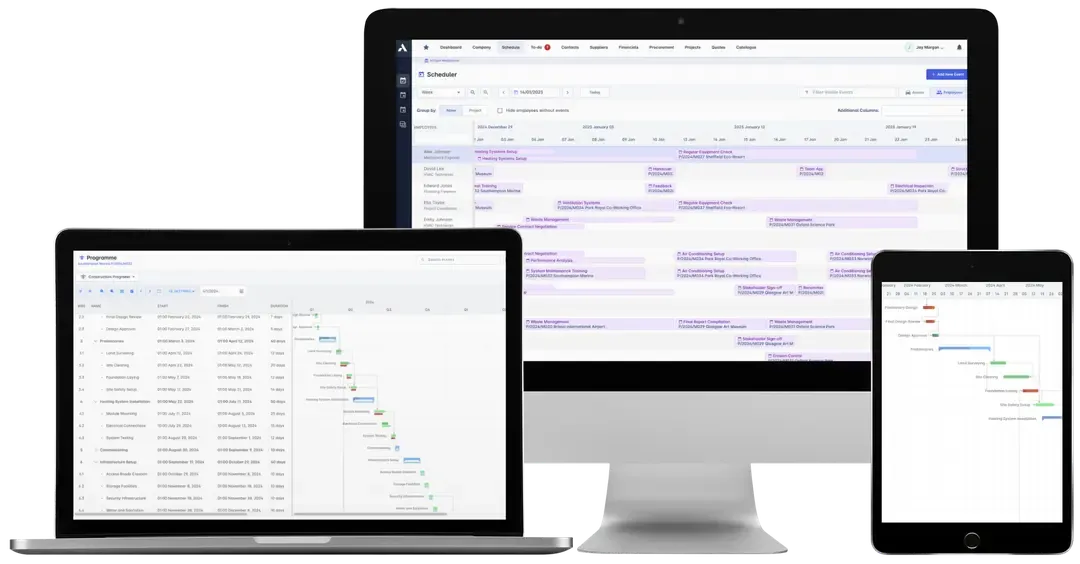

An example of Archdesk's interface, showing project tracking capabilities.

While other tools like Procore, Autodesk Construction Cloud, and Fieldwire offer valuable features for document control, BIM integration, or daily logs, Archdesk's holistic approach to resource leveling, custom buffer tracking, and integrated financial management makes it particularly well-suited for companies serious about implementing and maximizing the benefits of CCPM. It provides a comprehensive view that enables data-driven decisions crucial for effective critical chain management.

Real-World Adoption: Companies Building Smarter with CCPM

CCPM is not just a theoretical concept; it has been successfully adopted by various organizations across different industries, demonstrating its effectiveness in improving project delivery, especially in environments with high uncertainty and resource constraints.

Pioneers in Manufacturing and Aerospace

- Boeing: The aerospace giant has used CCPM to streamline its complex aircraft production processes, leading to significant reductions in lead times and improved resource utilization. This proves CCPM's capability in environments with intricate interdependencies and high stakes.

- Lucent Technologies: This telecommunications equipment company applied CCPM in its manufacturing operations, seeing enhanced resource productivity and faster project completion.

- Ricoh: In the printer manufacturing sector, Ricoh successfully implemented CCPM to achieve smoother resource flows and better production efficiency.

- NASA and Texas Instruments: These organizations, known for managing highly complex and long-duration projects, have also reportedly utilized CCPM within their project management frameworks to handle stringent resource requirements and manage risks effectively.

- Embraer: The Brazilian aerospace company used CCPM to reduce the development and launch time for a new plane by a significant margin, highlighting the method's ability to compress timelines for complex R&D projects.

- Eli Lilly & Company: A pharmaceutical company that piloted CCPM to manage R&D projects and move new pharmaceutical products from trials to initial manufacture more efficiently.

Growing Traction in Construction

While often less publicized than its use in manufacturing or aerospace, CCPM is gaining significant traction in the construction industry. It's recognized for its potential to improve time management, enhance project execution, optimize resource utilization, and achieve more reliable on-time project completion.

- Residential Construction: Studies and real-world examples show that residential builders applying CCPM can optimize resource use, manage constraints, and reduce overall project timelines. One report indicated that it can reduce buffer over-consumption by 30% in residential projects.

- Infrastructure Projects: CCPM has been reported to improve on-time delivery by up to 20% on projects like repaving and sitework, where external factors and resource management are critical.

The success stories emphasize a cultural shift: trusting the buffers and focusing on the overall project flow rather than micromanaging individual task deadlines. This shift often leads to surprising improvements in project speed and reliability.

Overcoming CCPM Implementation Challenges

Adopting any new project management methodology comes with its own set of challenges. While CCPM offers significant benefits, successful implementation requires addressing some common hurdles.

Addressing Resistance to Change

One of the biggest obstacles can be a cultural one: "We've always done it this way." Teams accustomed to CPM's individual task padding might initially resist the idea of removing that safety time and pooling it into centralized buffers. This requires strong leadership, clear communication, and training. Starting with a pilot project can help demonstrate the benefits of CCPM on a smaller scale, building confidence and buy-in within the organization. Educating teams that buffers are not "free padding" but rather critical tools for protecting the entire project's success is essential.

Simplifying Buffer Calculations and Usage

The concept of calculating and managing different types of buffers might seem complex at first. However, modern project management software like Archdesk can automate much of this "buffer math," making it far more manageable. Tools can help track buffer consumption in real time and provide alerts, simplifying the monitoring process for project managers. The key is to make buffer health visible and actionable, turning complex calculations into straightforward insights that guide decision-making.

Conclusion: Embracing a More Resilient Project Future

In the inherently uncertain world of construction, relying solely on the Critical Path Method, with its assumptions of ideal conditions and unlimited resources, often leads to frustration, delays, and cost overruns. Critical Chain Project Management provides a powerful and practical alternative. By shifting the focus from individual task padding to strategic buffer management and explicit consideration of resource constraints, CCPM offers a framework that is far more resilient to the real-world complexities of building projects.

Adopting CCPM means creating schedules that can adapt and breathe, rather than ones that crumble at the first sign of trouble. When integrated with a comprehensive construction management platform like Archdesk, CCPM's principles are brought to life, offering real-time visibility, optimized resource utilization, and improved communication. This synergy empowers construction professionals to move from reactive firefighting to proactive management, giving them a clearer picture of their project's true health and greater control over its destiny. For designers and project managers looking to achieve more reliable on-time, on-budget project deliveries, embracing the critical chain is a smart step towards building better.

Frequently Asked Questions (FAQ)

What is the main difference between CPM and CCPM?

CPM focuses on task sequences and durations, assuming unlimited resources, often leading to individual task padding. CCPM focuses on resource constraints and uses collective buffers to protect the entire project from uncertainty, aiming for shorter, more reliable timelines.

Why is CCPM better for construction projects?

Construction faces constant uncertainties like weather, material delays, and resource availability. CCPM’s strategic buffers absorb these shocks, its resource focus optimizes constrained resources, and its emphasis on single-task focus boosts efficiency, making projects more resilient and predictable.

How does Archdesk support CCPM?

Archdesk provides tools for real-time buffer tracking and alerts, efficient resource allocation, and integrated financial and communication management. This helps project managers monitor critical chain health, prevent bottlenecks, and make data-driven decisions that align with CCPM principles.

Are there real companies using CCPM in construction?

Yes, while specific construction company names are often proprietary, the principles of CCPM are increasingly applied in residential and infrastructure projects, showing benefits in reducing timelines and improving on-time delivery. Major companies in aerospace and manufacturing like Boeing and Embraer also successfully use CCPM.

Is it difficult to switch from CPM to CCPM?

Switching requires a shift in mindset and training to understand buffer management. It can be challenging, but starting with a pilot project and leveraging software like Archdesk to automate calculations and provide real-time insights can significantly ease the transition.

References

Critical Chain Project Management: A Comprehensive Guide - 6sigma.us

The Critical Chain Project Management method explained - critical-chain-projects.com

Critical Chain Project Management (CCPM) in Construction - PlanningEngineer.net

Critical Chain Project Management: Enhancing Construction - constructor.net.au