Alright, pull up a chair, grab a brew. Name's Mike – been crunching numbers for construction projects longer than some of you have been tying your own work boots. For years, my trusty sidekick was a beast of an Excel file. You know the one – countless tabs, formulas one wrong click away from blowing up your whole bid, and more versions than I've had hot dinners. We all had 'em. It was like a badge of honor, a complicated mess that only you (mostly) understood.

But times change, and even old dogs like me can learn new tricks. Today, I want to talk shop about construction estimating: the methods we use, the costs we juggle, and how moving from those clunky spreadsheets to something smarter, like Archdesk, actually made my job easier and our bids sharper. No fancy talk, just straight goods from one construction guy to another.

Top 3 Takeaways for Sharper Estimating

- Understand Your Methods: Knowing when to use a quick ballpark figure versus a detailed bottom-up estimate can make or break your bid. Each project stage and type demands a different approach.

- Excel Isn't Your Only Friend (or Foe): While familiar, spreadsheets are prone to errors and inefficiencies. Modern software offers integrated solutions that save time and improve accuracy dramatically.

- Integration is King: When your estimate seamlessly flows into project management and procurement, everyone's working from the same playbook, reducing mistakes and improving collaboration.

Why Bother Getting Estimates Right Anyway?

More Than Just Numbers on a Page

Let's be honest, estimation is the guts of any construction job. Get it right, and you're the hero who brings in profitable work. Get it wrong, and you're explaining to the boss why you're losing money or, worse, why you didn't even win the job. An accurate estimate is your roadmap. It tells you what you need, how much it'll cost, and gives the project team a clear target.

I remember one job, a small office fit-out. I used an old Excel template from a "similar" project. Big mistake. Didn't account for the new site being in a pricier part of town with stricter access. We won the bid, alright, but our labor costs went through the roof. That "small oversight" ate into our profit like nobody's business. Lesson learned: detail matters, and good estimating stops these headaches before they start.

The Wild West of Excel Estimating

How Every Company Built Its Own Spreadsheet Monster

For donkey's years, Excel was the king of construction estimating. Every company, big or small, had its own unique, often terrifyingly complex, spreadsheet. You'd inherit it, spend weeks figuring out its quirks, and then add your own layers of "genius" to it. Sound familiar?

Why Excel? Well, it was what we knew. It was flexible – you could add a column for anything, tweak formulas to your heart's content. Plus, it felt cheap because, hey, everyone's got Excel, right? No need for fancy software subscriptions or training, or so we thought.

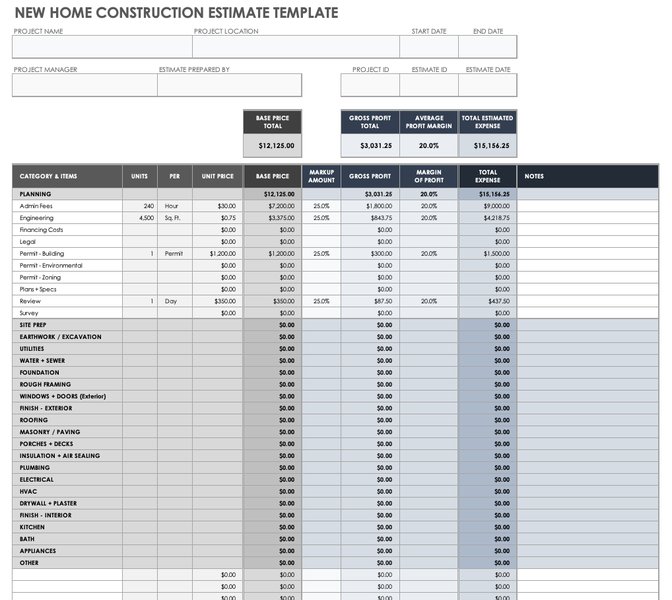

A typical sight: an estimate template in a spreadsheet program, familiar to many in the industry.

But let's not kid ourselves. It was a pain. One wrong formula, one deleted cell, and your whole bid could be shot. Version control? A nightmare. "Estimate_Final_V2_Mike's_Changes_ REALLY_FINAL.xlsx" – we've all been there. Sharing these massive files via email, hoping everyone was looking at the latest version, was a constant source of stress. Information was always out of date, leading to confusion and costly mistakes. Manually updating material prices, chasing subcontractor quotes, typing everything in… it was a time sink and a recipe for errors. We just accepted it as "the way things are done."

Different Ways to Skin the Cat: Estimating Methods

Choosing Your Weapon Wisely

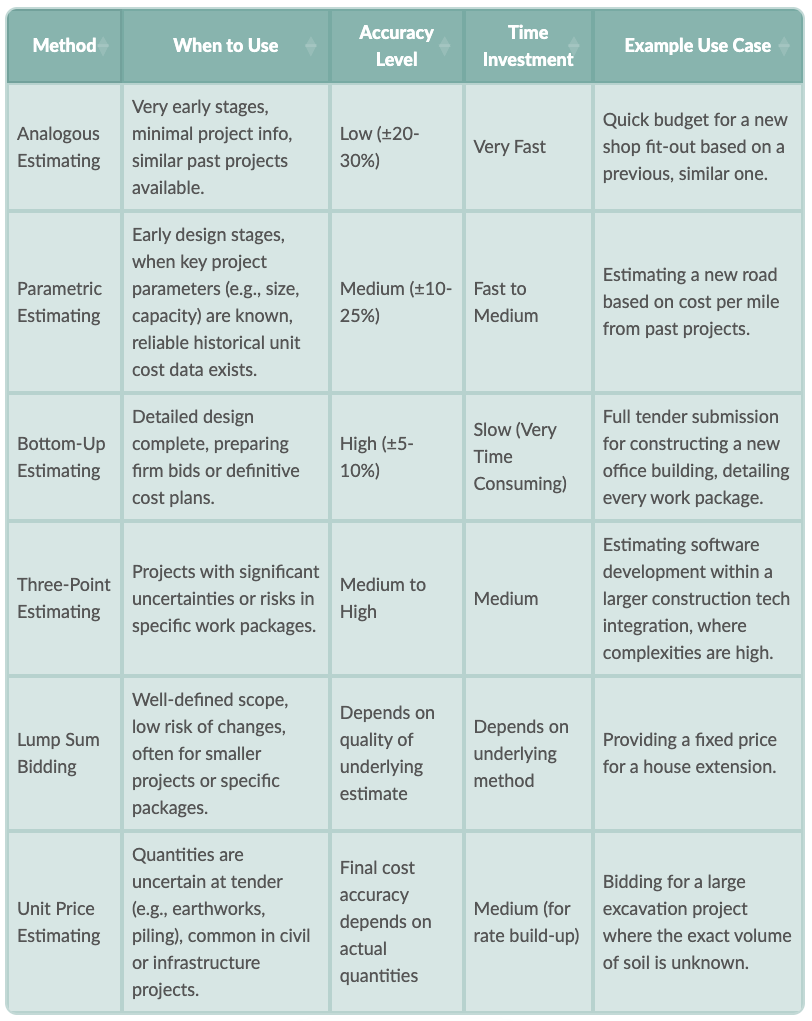

There isn't just one way to estimate a job. The method you pick usually depends on how much info you've got and what stage the project is in. Here are the main ones I've used over the years:

Analogous Estimating: The "Déjà Vu" Method

This is your "gut feeling" estimate. You look at a similar project you did in the past and say, "Well, that one cost X, so this new one, being a bit bigger, should be around Y." It’s quick, good for early ballpark figures when you barely have any drawings. For example, if a 2,000 sq ft warehouse cost £200,000 last year, you might roughly estimate a new 2,500 sq ft one at £250,000. But it's the least accurate because no two projects are truly identical. Location, material costs, site conditions – they all change.

Parametric Estimating: Using Unit Rates

This is a step up. You use historical data to find a cost per unit, like cost per square foot, cost per cubic meter of concrete, or cost per bed in a hospital. If you know laying bricks costs £X per square meter (including labor and materials), you measure the total square meterage of brickwork and multiply. More accurate than analogous, but you need good, reliable historical data for your parameters. For instance, if your data shows office fit-outs average £150 per square foot, a 5,000 sq ft office would be parametrically estimated at £750,000.

Bottom-Up Estimating: The Full Monty

This is the most detailed and, therefore, usually the most accurate method. You break the entire project down into the smallest individual tasks and materials – every nail, every hour of labor, every fitting. Then you cost each tiny piece and add it all up. Think of estimating a single room: so many meters of cable, X number of sockets, Y hours for the electrician, Z bags of plaster, etc. It takes a lot of time and detailed plans, but it gives you a solid, defensible number. This is what you'll use for your proper tender bids.

Three-Point Estimating: Hedging Your Bets

This one acknowledges that things can go wrong (or surprisingly well!). For each significant cost item, you come up with three estimates:

- Optimistic (O): If everything goes perfectly.

- Pessimistic (P): If everything that can go wrong does.

- Most Likely (M): Your realistic best guess.

You then use a formula, often ( (O + 4M + P) / 6 ), to get a weighted average. This helps account for risks and uncertainties. For example, pouring a foundation: Optimistic = £10,000, Most Likely = £12,000, Pessimistic (bad weather, supplier delay) = £16,000. The three-point estimate would be ( (£10,000 + 4 \times £12,000 + £16,000) / 6 = £12,333 ).

Lump-Sum Bidding

Here, you provide a single, fixed price for the entire scope of work. It's common for well-defined projects where the scope isn't expected to change much. The client likes the certainty, but as a contractor, you carry the risk if your estimate is off or unforeseen issues arise.

Unit Price Estimating

Instead of a total fixed price, you provide costs per unit of work (e.g., £X per cubic meter of excavation, £Y per linear meter of pipe laid). The final project cost is determined by multiplying these unit prices by the actual quantities measured on site. This is common for civil engineering projects or when quantities are uncertain at the tender stage.

ASPE Estimate Levels: From Fuzzy to Fine-Tuned

The American Society of Professional Estimators (ASPE) has a handy classification for estimates, showing how they get more accurate as the project gets more defined:

- Level 5 (Order of Magnitude): Very early, 0-2% project definition. Accuracy ±20-30%. Ballpark stuff.

- Level 4 (Intermediate/Feasibility): Early design, 5-20% definition. Accuracy ±10-25%. Is this project even doable?

- Level 3 (Preliminary Construction): More defined scope, 10-40% definition. Accuracy ±10-15%. Used for budget authorization.

- Level 2 (Substantive Construction): Detailed design, >90% definition. Accuracy ±5-10%. Used for bidding and cost control.

- Level 1 (Definitive Construction): Based on agreed contract costs, 100% definition. Accuracy up to ±2%. This is your baseline.

Deconstructing the Estimate: What Goes In?

The Nuts and Bolts of Your Costs

An estimate isn't just one big number. It's made up of several key ingredients. Miss one, and your profit could vanish.

Material Costs

This is all the physical stuff: concrete, steel, timber, bricks, pipes, paint, screws – you name it. You need accurate quantity takeoffs (measuring how much of everything you need) and up-to-date prices. Don't forget to add a percentage for waste (e.g., 5-10% for cut-offs or damaged goods). If you need 100m² of tiles priced at £20/m², that's £2,000. Add 10% for waste (£200), making it £2,200.

Labor Costs

This is what you pay your crew. You need to figure out how many hours each trade (carpenter, plumber, electrician) will spend on each task, then multiply by their hourly rate. Remember to include "on-costs" like National Insurance, pension contributions, holiday pay, and benefits – these can add 20-30% or more on top of the basic wage. If a job takes 100 labor hours at £25/hour basic, that's £2,500. Add 30% for on-costs (£750), and your labor cost is £3,250.

Equipment Costs

This covers machinery and tools – excavators, cranes, scaffolding, power tools. If you own it, there's depreciation, maintenance, and fuel. If you rent it, there are hire fees. Factor these in per day or per week for the duration they're needed.

Subcontractor Costs

For specialized work like M&E (mechanical and electrical), roofing, or specialist finishes, you'll often use subcontractors. Get detailed quotes from them and plug those figures into your main estimate. Make sure their scope matches yours perfectly to avoid gaps.

Indirect Costs (Overheads)

These are the costs of just being in business, not tied to one specific project: office rent, utilities, admin staff salaries, insurance, software subscriptions. You need to allocate a portion of these to each job, usually as a percentage of the direct project costs. If your annual overheads are £100,000 and you do £1,000,000 of work, your overhead recovery rate is 10%.

Contingency

This is your "rainy day" fund. Construction is unpredictable. Bad weather, unforeseen ground conditions, material price spikes – stuff happens. A contingency sum (often 5-15% of the total direct and indirect costs, depending on project risk) gives you a buffer. For a £500,000 project, a 10% contingency is £50,000.

Markup (Profit)

This is why you're in business! It's the amount you add on top of all your costs to make a profit. Your markup needs to be competitive enough to win bids but high enough to keep your business healthy. This can vary wildly based on market conditions, risk, and your company's financial goals.

Comparing Estimation Approaches: A Quick Glance

To help you choose the right estimating method, here's a table summarizing their key features. Understanding these differences is crucial for accurate bidding and project planning.

Tips from the Trenches: Estimating Best Practices

Little Things That Make a Big Difference

After years of doing this, I've learned a few things (often the hard way):

- Know Your Scope, Inside Out: Read all the documents – drawings, specs, contracts. If something's unclear, ask! Scope gaps are estimate killers.

- Thorough Quantity Takeoffs: Garbage in, garbage out. If your quantities are wrong, your estimate is wrong. Double-check, or get someone else to.

- Get Multiple Quotes: Don't rely on one supplier or subbie. Get at least three quotes and compare them like-for-like.

- Visit the Site: Pictures don't tell the whole story. Access issues, ground conditions, existing structures – a site visit can reveal costly surprises.

- Account for Location: Labor and material costs vary massively by region. Use local pricing.

- Factor in the Schedule: A tight schedule might mean overtime or expedited deliveries, adding cost.

- Don't Forget the Small Stuff: Permits, temporary facilities, site cleaning – these little costs add up.

- Use Historical Data (Wisely): Track actual costs from past jobs to refine your future estimates. But always adjust for current conditions.

- Stay Organised: Keep your estimates clear, logical, and well-documented. You (or someone else) will need to understand them later.

- Talk to Your Team: Project managers and site supervisors know how things get built. Their input is invaluable.

- Review, Review, Review: Before submitting any bid, get a fresh pair of eyes to review it.

The Game Changer: Swapping Spreadsheets for Smart Software

Why I Kissed My Excel Monster Goodbye for Archdesk

I'll admit, I was skeptical about specialized estimating software. "My Excel sheets work fine!" I grumbled. But the constant errors, the time wasted updating things manually, the stress of version control… it was wearing thin. Then, we made the switch to Archdesk.

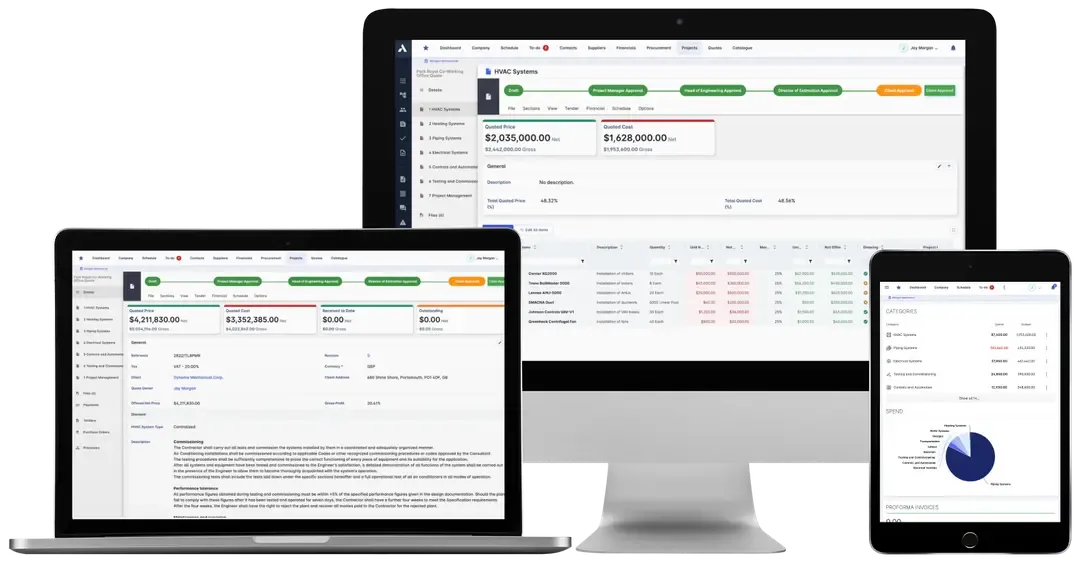

Suddenly, estimating wasn't a standalone, isolated task. With Archdesk, the estimate I create becomes the backbone of the entire project. Here’s how it made a difference:

- The Estimate IS the Scope/BOQ: Once I finalize an estimate in Archdesk, it automatically generates the Scope of Work (SoW) and Bill of Quantities (BOQ). The project managers and the procurement team use this *same data* for their tasks. No more re-typing, no more conflicting versions. Everyone's singing from the same hymn sheet.

- Real-Time Progress Tracking: The PMs report site progress directly against the BOQ items from my estimate. We can see, in real-time, how much work is done, what it's costing, and if we're on track financially.

- Always-Current Material Prices: Archdesk can link to material catalogs with the latest procured prices. If our procurement team negotiates a new rate for concrete, that updated price can be available when I'm building my next estimate. No more digging through emails or old price lists.

- Streamlined RFQ & Subbie Bids: The RFQ (Request for Quote) and bidding module is a lifesaver. I can send out quote requests to suppliers and subcontractors directly from the platform. Their prices come back into the system, making it easy to compare bids side-by-side and select the best ones. This means I'm using fresh, competitive pricing in my estimates.

It's not just about making *my* job easier. The whole company benefits. Information flows smoothly from estimate to execution. Errors are down, communication is up, and we're making better decisions because we have better data.

Modern estimating software can provide powerful tools for managing costs and materials.

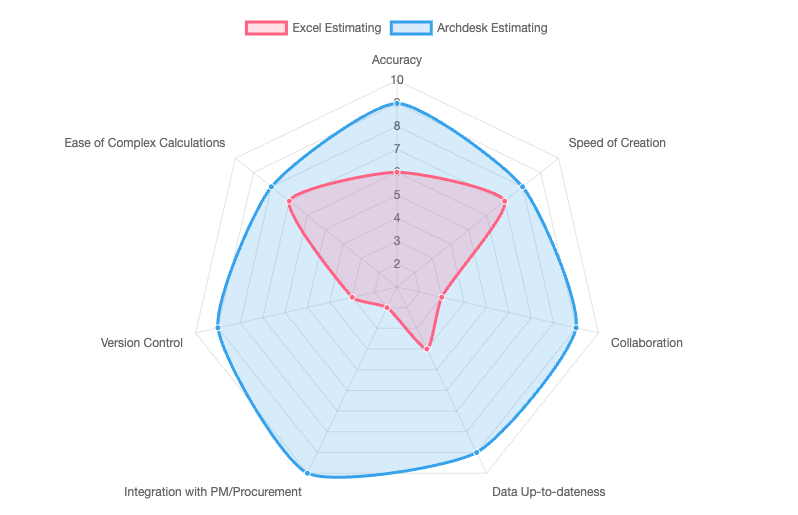

Excel vs. Archdesk: A Quick Comparison

This chart visually represents key differences between traditional spreadsheet-based estimating and using an integrated software solution like Archdesk. The scores (out of 10, where 10 is best) are my take on how they stack up for an estimator.

As you can see, while Excel might feel familiar for quick calculations, a dedicated system like Archdesk pulls ahead in areas critical for modern construction businesses: accuracy, real-time data, integration, and collaboration.

What About the Competition?

Sure, there are other big names out there – Procore, Autodesk Construction Cloud, Viewpoint, Buildertrend, and the like. Many of them are decent project management tools. But what I found with Archdesk was how tightly it connected the estimating part with everything else. It wasn't just an add-on; the estimate truly became the project's financial DNA, flowing naturally into procurement, cost control, and reporting. For an estimator, that seamless link is gold.

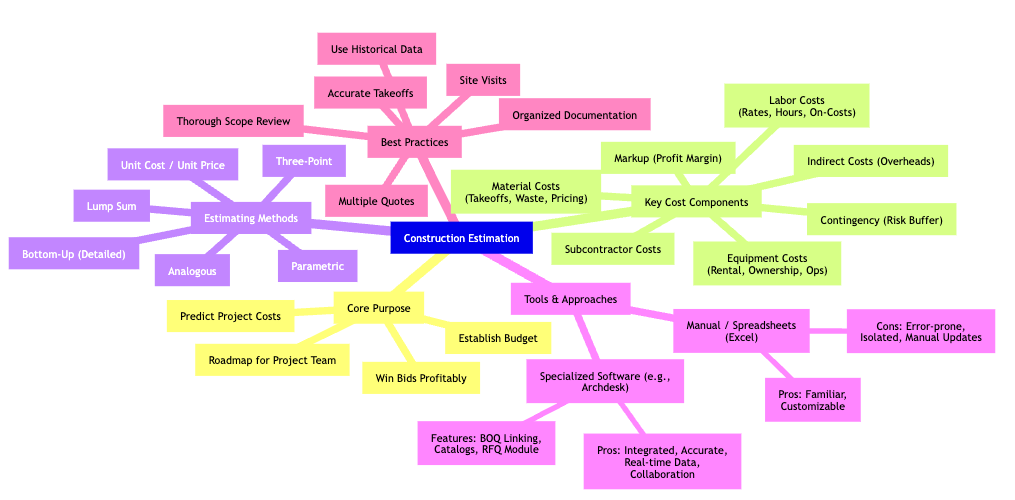

Mindmap of Construction Estimation

Visualizing the Estimating Universe

To give you a bird's-eye view of what we've discussed, here's a mindmap. It lays out the main areas of construction estimation, from the core components to the methods and tools involved. It helps to see how all these pieces fit together in the complex puzzle of predicting project costs.

This mindmap shows that successful estimation isn't just about one thing; it's about understanding how all these different elements – from the type of estimate you prepare to the tools you use and the cost details you include – work together to create a reliable financial picture of a project.

Frequently Asked Questions (FAQs)

What's the hardest part about switching from Excel to dedicated estimating software?

Honestly, for me, it was letting go of my old habits and trusting the software. You get so used to your own spreadsheets, quirks and all. Learning a new system takes a bit of time and patience. But once you see the benefits – like less manual data entry and better accuracy – you wonder why you didn't switch sooner. The initial setup of your standard items and rates can also take a bit of effort, but it pays off massively in the long run.

Can small construction companies really benefit from software like Archdesk, or is it just for big players?

Absolutely! I used to think it was just for the big outfits too. But good software can scale. Even for a smaller company, the time saved, the reduction in errors, and the improved professionalism in your bids make a huge difference. It helps you compete better. Plus, having all your project info in one place, from estimate to completion, is a massive advantage for staying organized, no matter your size.

How does construction estimating software help with change orders?

This is a big one. With software, your original estimate is clearly documented and broken down. When a change order comes up, you can easily see how it impacts the original scope and costs. You can quickly price the changes using the same rates and structure, create a professional variation document, and track its approval. It's much cleaner and more transparent than trying to bolt changes onto an already complicated spreadsheet, and helps ensure you get paid fairly for extra work.

How often should I update my material and labor rate databases in the software?

As often as practical, especially in volatile markets! For key materials, check with suppliers monthly or even more frequently if prices are changing fast. Labor rates might be updated annually based on union agreements or market reviews. The beauty of some software is that if your procurement team updates a price for a material they've just bought, that can feed back into your master database, so you're always working with the most current info. For subbie rates, you'll typically get fresh quotes for each specific job via the RFQ process.