Key Insights for Smart Builders

- Ditching the "Race to the Bottom": Purely chasing the lowest upfront price in construction often leads to hidden costs, quality issues, and project delays. It's a short-sighted game that rarely pays off in the long run.

- Strategic Sourcing as a Blueprint for Value: This approach focuses on building robust, long-term partnerships with suppliers, prioritizing total cost of ownership (TCO), material quality, and reliability over just the initial purchase price.

- Technology as Your Procurement Partner: Modern procurement software transforms strategic sourcing from a theory into a practical advantage, offering data-driven insights, automating processes, and improving communication to boost project success.

We all know the situation: a project needs concrete, steel, or specialty insulation, and the clock is ticking. The immediate impulse might be to grab the quickest, cheapest option. This "tactical buying" approach feels like a win in the moment, a swift checkmark on the to-do list. But what if that quick win actually sets you up for a series of headaches down the line? Imagine getting materials that don't quite meet standards, causing rework, or suppliers who vanish when you need them most. That's the hidden cost of the "race-to-the-bottom" in construction procurement.

This article isn't about shaming quick decisions. Sometimes, tactical buying is necessary, like for a sudden, low-risk emergency. But for the vast majority of your project needs, especially critical components, a more thoughtful path—what we call "strategic sourcing"—can make all the difference. It's about designing your procurement process with the same care you design a building: focusing on foundational strength, long-term performance, and sustainable value. We'll explore why moving beyond mere price obsession can lead to better supplier relationships, top-notch material quality, and surprisingly, greater long-term savings, even if the initial sticker price seems a bit higher. We'll also see how smart software can be your best friend on this journey, with examples from both US and UK companies.

The Pitfalls of Purely Tactical Buying

Think of tactical buying as ordering takeout when you're suddenly hungry. It solves the immediate problem. In construction, this looks like calling a few suppliers, taking the lowest quote for a specific item, and moving on. It's reactive, transactional, and usually driven solely by the lowest upfront price for a single purchase. While it offers speed and simplicity, relying heavily on it for crucial project components often comes with a hefty hidden price tag.

Why the Lowest Price Can Cost You the Most

- Quality Compromises: The cheapest rebar might be inconsistent in strength, or the lowest-bid drywall could be prone to cracking. This leads to costly rework, project delays, and a dent in your reputation. A US regional contractor in Texas, for example, once chased the lowest price for structural steel, only to receive material that arrived late and missed critical site inspections, delaying a foundation pour. The supposed $5,000 "savings" on materials quickly ballooned into $50,000 in labor and equipment standby costs.

- Unreliable Deliveries: Suppliers focused on rock-bottom prices often cut corners on logistics or might not prioritize your order. Delayed materials mean idle crews, missed deadlines, and contractual penalties.

- Shallow Supplier Relationships: Constantly jumping from one vendor to the next for the cheapest deal prevents you from building trust or gaining preferential treatment. When you have a genuine emergency, who's going to go the extra mile for you if you're just another fleeting transaction?

- Missed Innovation: Suppliers who are always squeezed on price have little incentive to share new, more efficient materials or methods with you. You miss out on potential advancements that could make your projects better and more profitable.

It's like trying to win a game of bargain bingo. You might hit the jackpot once, but more often, you're left with materials that don't quite fit your project's needs. While general construction management platforms like Procore or Autodesk Construction Cloud track purchases effectively, they don't inherently push you toward building deeper, strategic supplier relationships necessary to avoid these pitfalls.

Embracing Strategic Sourcing: Building Lasting Value

Strategic sourcing is the grown-up version of procurement. It's a thoughtful, long-term approach to acquiring what you need, focusing on getting the most value from your purchasing decisions. It's about building strong, mutually beneficial relationships with key suppliers and making choices that align with your overall business goals, not just today's lowest price. Think of it as carefully selecting the right architectural firm for a multi-year project, rather than just picking the cheapest one for a single design sketch.

Better Supplier Relationships: The Cornerstones of Trust and Efficiency

In construction, strong relationships with suppliers are fundamental. They are built on trust, open communication, and a shared understanding of project goals. When you treat suppliers as partners, not just vendors, everyone wins.

- Mutual Trust and Transparency: Trusted suppliers are more likely to be upfront about potential issues, lead times, or market pricing changes. This transparency allows you to plan better and mitigate risks more effectively. They're not just selling; they're genuinely helping you succeed.

- Improved Communication: Clear and open communication ensures everyone is on the same page regarding specifications, delivery schedules, and any changes. This reduces misunderstandings, costly errors, and friction.

- Preferential Treatment: Strong relationships can mean priority access to materials during shortages, faster response times, or better payment terms when you need them. Balfour Beatty, a major UK construction firm, emphasizes building trust with supply chain partners to deliver their core values. This isn't about the cheapest bolt; it's about reliable partners who align with their goals.

- Joint Problem Solving: When issues inevitably arise on a project, strong relationships mean suppliers are more willing to collaborate on solutions, rather than just pointing fingers.

Improved Material Quality: Building it Right the First Time

Strategic sourcing prioritizes quality alongside cost. Saving a bit upfront on materials only to spend a lot more fixing problems later is a bad deal. High-quality materials lead to less rework, faster installation, and a better finished product.

- Consistent Quality: Working with trusted suppliers means you get materials that consistently meet your specifications. This significantly reduces the risk of defects and costly delays on site. For example, a mid-sized US general contractor, "Apex Construction," faced issues with inconsistent drywall quality from various tactical suppliers. By shifting to a strategic sourcing approach, they partnered with a single, larger supplier who consistently delivered high-grade material. The reduction in rework and faster installation times more than made up for a slightly higher per-sheet cost.

- Access to Better Materials: Strategic partners are often at the forefront of material innovation. They can introduce you to newer, more efficient, or more sustainable products that can improve your project's performance or reduce long-term maintenance costs.

- Reduced Waste and Rework: High-quality materials mean less waste from defective products and fewer instances of needing to tear out and reinstall components, directly saving labor and material costs.

Long-Term Cost Savings: The True Measure of Value

While initial prices might seem higher with strategic sourcing, the actual cost savings become clear over time. This is where the concept of Total Cost of Ownership (TCO) becomes your guiding light.

- Total Cost of Ownership (TCO): Strategic sourcing looks at the complete cost, not just the purchase price. This includes everything from transportation, storage, installation time, rework, maintenance over the lifespan of the material, and even disposal. A cheaper material that is difficult to install or breaks easily will have a higher TCO.

- Volume Discounts and Favorable Terms: Long-term commitments with strategic suppliers can lead to better pricing, more favorable payment terms (like extended payment windows), and discounted rates for large or recurring orders.

- Reduced Administrative Costs: Managing fewer, more reliable suppliers reduces the time and effort spent on procurement activities, such as issuing multiple requests for quotes (RFQs), managing numerous invoices, or resolving disputes.

- Risk Mitigation: Strong supplier relationships and consistent quality reduce project risks related to delays, material shortages, and quality failures, all of which are major cost drivers in construction.

A large UK property developer, "CityScape Developments," traditionally sourced plumbing fixtures based on the lowest bid for each project, leading to varied quality and maintenance issues. By adopting a strategic sourcing model and partnering with a major European plumbing supplier, their initial per-unit cost was slightly higher. However, the strategic partnership brought standardized product lines, consistent warranty support, volume discounts across multiple projects, and better lead times. The overall reduction in project delays, maintenance issues, and administrative overhead resulted in significant long-term savings, proving TCO was a far better metric than initial purchase price.

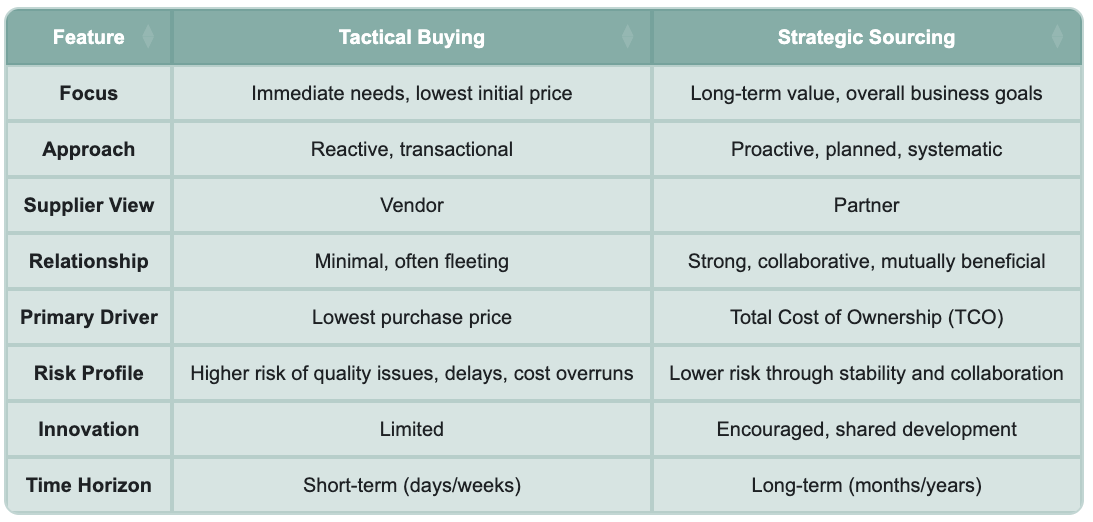

Strategic vs. Tactical: A Clear Divide

Here’s a quick overview of how these two approaches stack up:

The Power of Procurement Software: Your Smart Assistant

Making the shift from reactive tactical buying to proactive strategic sourcing isn't just about changing your mindset; it often requires the right tools. This is where construction procurement software comes into play. It's not just a fancy toy; it's a critical enabler for smart procurement, helping you automate, analyze, and optimize your purchasing decisions.

.webp)

Modern procurement software provides critical insights through intuitive dashboards.

How Technology Elevates Your Sourcing Game

- Automated Supplier Scorecards and Performance Tracking: Manually tracking supplier performance is a nightmare. Software can automatically gather data on delivery times, material quality, compliance, and even innovation. This gives you clear, objective data on who your best suppliers are and who needs to improve. Gartner notes that automated scorecards can help extract innovative ideas from suppliers at a lower cost.

- Streamlined Communication and Collaboration: Good software offers centralized platforms for communication, RFQs, bid management, and document sharing. This reduces back-and-forth emails, minimizes missed messages, and speeds up responses. Platforms like 4castplus, for instance, offer RFQ and bid management systems with built-in vendor portals.

- Enhanced Visibility and Data Analytics: With all procurement data in one place, you get a clear, real-time view of your spending, supplier performance, and material availability. This data is essential for making informed strategic decisions, spotting cost-saving opportunities, and optimizing your supply chain. This move to digital solutions helps you gain a holistic view of your company's purchasing ecosystem.

- Contract Management and Compliance: Software can manage contracts, track terms, and automate reminders for renewals or performance reviews. This ensures you're always compliant and can negotiate new terms effectively.

- Cost Control and Budget Monitoring: By automating tasks and providing detailed insights into costs, procurement software helps manage expenses and keeps projects within budget. Solutions like RIB BuildSmart focus on tight control over the procurement process, managing the complete requisition-to-payment cycle with enhanced budget visibility.

While general construction management software like Procore, Autodesk Construction Cloud, or Viewpoint are great for overall project management, specialized procurement tools (like Archdesk, Doxa, RIB Software’s BuildSmart, and 4castplus) offer deeper functionality designed specifically for the complexities of construction procurement. They help businesses transition from tactical to strategic sourcing by providing the digital infrastructure for data analysis and collaboration.

Real-World Success Stories: Building Smarter

Let's look at how companies in the US and UK have put strategic sourcing into practice, transforming their operations and achieving significant results.

US Companies Leading the Way

- Fluor Corporation (Texas): This global engineering and construction giant shifted to strategic sourcing years ago. Instead of always chasing low bids for piping and machinery, they partnered with key suppliers for ongoing projects. This led to more reliable materials and a reported 15% reduction in waste through better planning and coordinated deliveries.

- Bechtel Corporation (Virginia): For a major infrastructure project, Bechtel used strategic sourcing to work closely with suppliers from the early stages. By leveraging their procurement software (even adapting general project management tools like Procore for deeper tracking), they achieved improved material quality and fewer delays compared to rivals sticking to tactical methods. This approach also led to innovative ideas from partners, cutting costs by 8% over two years.

- Sunbelt Builders (Texas): A regional builder, Sunbelt, used strategic sourcing software to consolidate steel purchases across multiple job sites. By cutting their supplier list from ten to three trusted partners, they saved 8% on steel costs and dramatically reduced delivery variance from ±7 days to a tight ±2 days, keeping projects on schedule.

- STO Building Group (New York): This construction leader has implemented procurement solutions that centralize vendor management and automate processes. This has resulted in faster communication with suppliers, leading to better material quality and fewer errors across their diverse portfolio of projects.

UK Companies Building Differently

- Laing O'Rourke (Dartford): This major UK contractor has fully embraced strategic sourcing. By focusing on building trust with their vendors, they secure high-quality steel and advanced technology on time. This approach has led to smoother projects and consistent repeat business, reinforcing the value of long-term partnerships.

- Morgan Sindall (UK-wide): Moving away from purely tactical buying for general site materials, Morgan Sindall has shifted to strategic ties. This has resulted in significantly better delivery times and consistent quality for their diverse projects, demonstrating that a focus on relationships pays dividends.

- Northern Civil Engineering (Manchester): This firm established a two-year framework agreement for asphalt with a key supplier. Through this strategic partnership, they negotiated volume discounts and shared mill performance data, leading to a verifiable 7% cost savings and improved material consistency.

- London Infrastructure Group: This group piloted a Supplier Relationship Management (SRM) tool to manage their five most critical suppliers. The result was a dramatic decrease in quality defects on precast panels, falling from 4% to an impressive 1.2%, showcasing the impact of focused supplier management.

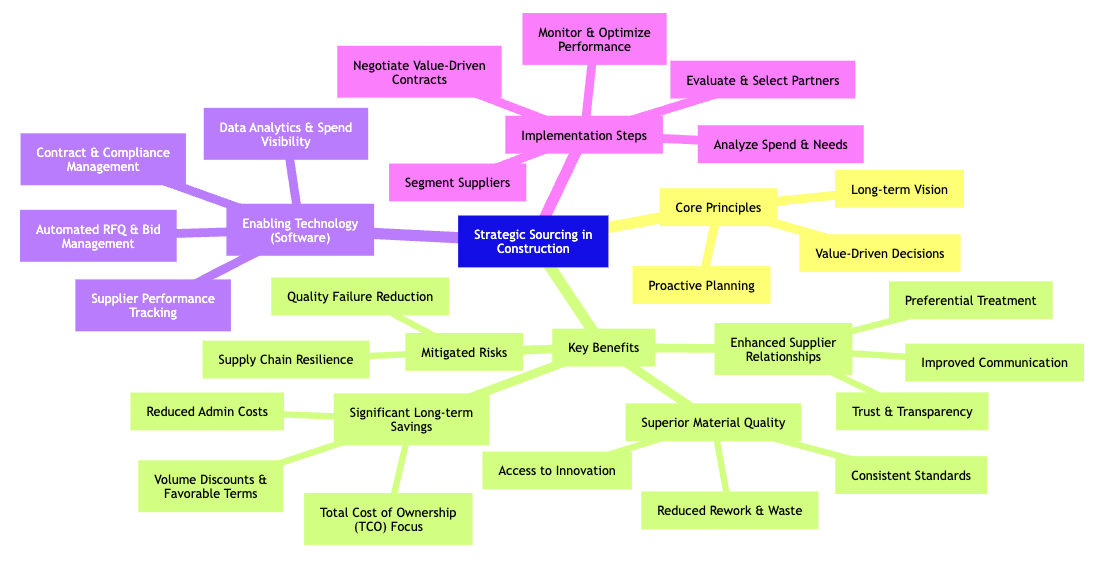

This mindmap illustrates the interconnected components and benefits of adopting a strategic sourcing framework in construction.

Building Your Strategic Sourcing Framework: A Practical Guide

Shifting from tactical buying to strategic sourcing isn't an overnight change. It's a methodical journey that requires commitment and the right tools. Here’s a simplified blueprint to get you started:

Step 1: Get Smart About Your Spending

Before you make any changes, understand where your money is going. Gather all your past procurement data. Use analytics dashboards (many procurement software solutions offer these) to identify your top spending categories, who your main suppliers are, and what materials consistently cost the most. This helps you see opportunities for consolidation or negotiation.

Step 2: Segment Your Suppliers

Not every screw or nail needs a deep, strategic relationship. Classify your suppliers based on their importance, the risk they pose, and the value they bring. Focus your strategic efforts on the top 20% of suppliers for critical materials (like structural steel, concrete, or major equipment), where a long-term partnership will have the biggest impact. Low-value, off-the-shelf items can still be handled more tactically.

Step 3: Define Your Partnership Criteria

Beyond price, what else matters? Develop clear criteria for selecting strategic partners. This should include quality standards, delivery reliability, financial stability, commitment to sustainability, innovation capabilities, and willingness to collaborate. Use standardized request for proposal (RFP) or RFQ templates that include these criteria, not just a price line.

Step 4: Negotiate for Value, Not Just Price

When negotiating with potential strategic partners, aim for multi-year agreements with clear key performance indicators (KPIs). Discuss delivery schedules, quality guarantees, payment terms, service level agreements, and even provisions for innovation or joint development. It’s about building a win-win scenario.

Step 5: Actively Manage Relationships and Performance

Once contracts are in place, actively manage the relationship. Schedule regular performance reviews (quarterly business reviews are common), maintain open communication, and collaborate on solving any issues that arise. Use your procurement software to track performance against agreed-upon metrics. This iterative process ensures you're always getting the best value and continuously improving.

Proactive supply chain management is a cornerstone of strategic sourcing.

Common Roadblocks and How to Navigate Them

Making any significant change in how you operate can face resistance. Strategic sourcing is no different. Here are a few common objections and how to address them:

- "Strategic sourcing is too slow or too much work upfront."

It's true, it requires more initial effort than a quick tactical buy. However, this upfront investment pays off significantly by reducing problems, delays, and unexpected costs later. Start small: pick one critical material category or a single pilot project to demonstrate the benefits before rolling it out company-wide. - "Our team is comfortable with the old ways."

Old habits are hard to break. Show your team the clear benefits of strategic sourcing, how it can reduce their daily headaches (less chasing missing materials, fewer quality issues), and ultimately make their jobs easier and more successful. Celebrate early wins and provide training on new processes and software. - "Procurement software is expensive."

Compare the cost of a software license against the cost of a single major project delay, a significant material quality failure, or the administrative time saved. The return on investment (ROI) often becomes clear very quickly when you factor in Total Cost of Ownership. Many providers offer tiered pricing or pilot programs. - "Our data is messy, we can't analyze it."

This is precisely why modern procurement software is so valuable. It centralizes and structures your data, making it clean and accessible for analysis. While getting started might involve some data cleanup, the long-term benefits of clear data for decision-making are immense.

Frequently Asked Questions

What is the main difference between strategic sourcing and tactical buying?

Strategic sourcing focuses on long-term value, building partnerships, and looking at the total cost of ownership (TCO) for critical materials and services. Tactical buying, on the other hand, is reactive, short-term, and primarily driven by getting the lowest upfront price for immediate needs.

Why is focusing on "Total Cost of Ownership (TCO)" important?

TCO considers all costs associated with a purchase over its entire lifecycle, including purchase price, delivery, installation, maintenance, and disposal. A seemingly cheaper material might have higher TCO due to poor quality, frequent breakdowns, or difficult installation, leading to greater expenses over time. TCO provides a more accurate picture of true cost.

Can I use both strategic sourcing and tactical buying?

Absolutely! It's not an either/or situation. Tactical buying is appropriate for low-risk, low-value, or emergency purchases where extensive analysis isn't necessary. Strategic sourcing should be applied to critical materials, services, and long-term needs where quality, reliability, and supplier relationships have a significant impact on your project's success and overall business health.

How does software help with strategic sourcing?

Procurement software centralizes data, automates tasks like RFQs and bid management, tracks supplier performance, and provides analytics dashboards. This helps you make data-driven decisions, streamline communication, manage contracts, and gain visibility into your spending, freeing up your team to focus on strategic activities.

Are there examples of US or UK companies successfully using strategic sourcing?

Yes, many. In the US, companies like Fluor Corporation and Bechtel have used strategic sourcing to reduce waste, improve quality, and gain innovation from suppliers. In the UK, firms like Balfour Beatty and Laing O'Rourke emphasize building long-term, trusting relationships with partners to ensure consistent quality and reliable delivery across their projects.

Conclusion: Build Smart, Not Just Cheap

The choice between strategic sourcing and tactical buying in construction is a fundamental one that impacts every aspect of a project, from quality and schedule to budget and reputation. While tactical buying has its place for minor, immediate needs, a sole reliance on it can lead to a costly "race to the bottom" that compromises quality and long-term financial health. It's like building a beautiful house on a shaky foundation – it looks good at first, but problems will eventually surface.

Strategic sourcing, on the other hand, embraces a holistic, value-driven approach. By fostering strong supplier relationships, ensuring consistent material quality, and focusing on total cost of ownership, construction companies can achieve significant long-term savings and build a more resilient, efficient, and profitable operation. The right procurement software is no longer a luxury but an essential partner in this journey, enabling data-driven decisions, streamlining processes, and empowering a truly strategic approach to how you acquire everything you need to build amazing spaces. It's about building smart, not just cheap, and that's a framework for value that truly stands the test of time.

References

The strategic era of procurement in construction | McKinsey

Our Procurement Strategy - Balfour Beatty

Tactical Sourcing vs. Strategic Sourcing: Meaning & Differences - GEP

Building Resilience in the Supply Chain: Predicted Challenges and ... - Procure Partnerships

The Importance of Strong Relationships in the Construction Industry - ProjectMark