We take a deep dive into the world of construction estimates, discussing the main techniques and best practices to achieve success.

Construction estimates. These two seemingly innocuous words are the cause of more than their fair share of stress for contractors everywhere.

Here’s the deal: The goal of any contractor is to win projects, deliver them to budget and get as high a profit margin as you can.

There are no two ways about it: If you want to succeed at these objectives, you need construction estimating.

But as anybody who’s ever tried cost estimating in construction will tell you, it’s fraught with complexity. So, I hear you ask, how do you get it right?

Good news – you’ve come to the right place.

Types of construction estimates

To succeed at construction cost estimating, it’s helpful first to understand the different ways jobs can be costed.

There are five methods for estimating cost in construction, each being used at a different stage of the bid or building process.

Crucially, even if you’re putting a lot of work and detail into your pricing – you could be shooting yourself in the foot if you’re using the right estimate at the wrong time.

Each estimate has a subtly different job to do – so it’s helpful to understand the differences between each stage to make sure you’re getting it right.

“As an ex-construction estimator, I have seen first-hand how important accurate project information is to the success of a project. When project documents are outdated or incomplete, it can lead to incorrect estimates, cost overruns and delays.”

Danny Mitchell, Archdesk Head of Content and former Construction Estimator

Here are the five main types of construction estimates:

Preliminary estimate

A preliminary estimate is generally used to assess the feasibility of a project.

The goal is to produce a headline figure, from which the contractor can decide whether it’s worth pursuing the project through the bid process.

Generally, this estimate is produced from historical data of similar jobs.

The goal is to eliminate proposals that aren’t feasible, so you can avoid putting hours of work into detailed estimates for projects that just aren’t going to happen.

Detailed estimate

As the name would suggest, this estimate looks to break the project down into more detailed chunks.

In this stage, elements like materials, equipment and labour are costed individually to create a more focused outline of the project costs.

Generally, this estimate will be based on completed drawings and layout plans, as well as a project specification document.

Quantity cost estimate

A quantity cost estimate breaks the prices down further – into individual units based on the actual amounts of materials or labour hours required.

If you were costing a flooring job, for instance, you would generally calculate the square foot area to be covered and the number of tiles required to fill it.

Then, pricing would be estimated based on the market value of tiles and the number needed.

The goal here is to update the detailed estimate with a clearer outline of material and labour costs – as the amount of these needed and the retail price available can vary from project to project.

Crucially, the quantity cost estimate lays the basis for the actual budget you bid for and spend.

Bid cost estimate

The bid cost estimate is like the quantity cost and involves much of the same information.

The only difference is once the direct project costs have been estimated, a series of other indirect expenses will be added to the estimate, including overheads and profit margin.

This is the definitive estimate that will be shown to the client and decide whether you’ll win the project.

Control cost estimate

The most detailed construction estimates in the world rarely survive contact with the ever-volatile reality of construction projects.

Prices change, subcontractors are unpredictable and the weather can quite literally rain on your parade.

That’s what the control estimate is for.

This is a live, updating estimate that’s used throughout the length of the project.

The goal is to track the real project costs against the estimate – and update where necessary.

It uses information about actual materials purchased and hours worked to diagnose how on-track your construction budget is and provide an estimated cost-to-completion.

How to win at construction estimating

Estimating costs in construction is a real double-edged sword.

Go too high and you risk losing the bid, go too low and you might end up seriously eating into your profit margins.

So, what’s the solution?

There’s no one-size-fits-all trick to this. As always, it’s important to report, learn and adapt.

But if you follow these tips, you’ll be well on your way to construction estimating success.

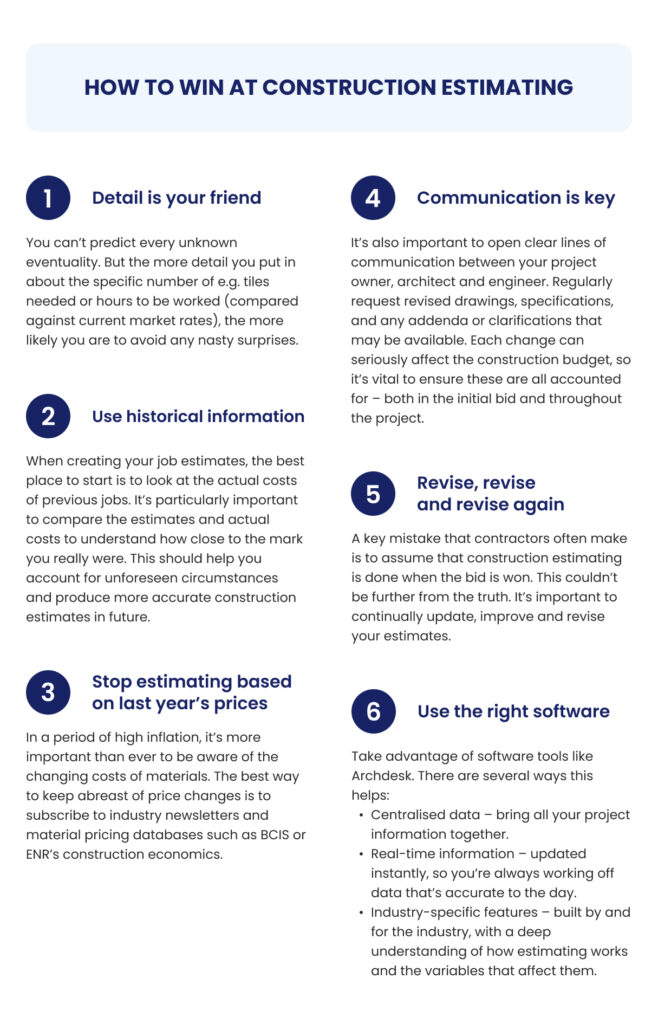

Detail is your friend

Detail makes a huge difference in construction estimates – which is why there are so many different stages to the estimating process.

You can’t predict every unknown eventuality.

But the more detail you put in about the specific number of e.g. tiles needed or hours to be worked (compared against current market rates), the more likely you are to avoid any nasty surprises.

Use historical information

No construction project has ever taken place in theory – so why should your estimates?

When creating your job estimates, the best place to start is to look at the actual costs of previous jobs.

These will better reflect the ever-fluctuating realities of projects on the ground.

It’s particularly important to compare the estimates and actual costs to understand how close to the mark you really were.

This should help you account for unforeseen circumstances and produce more accurate construction estimates in future.

Stop estimating based on last year’s prices

In a period of high inflation, it’s more important than ever to be aware of the changing costs of materials.

The best way to keep abreast of price changes is to subscribe to industry newsletters and material pricing databases such as BCIS or ENR’s construction economics.

Communication is key

It’s also important to open clear lines of communication between your project owner, architect and engineer.

Regularly request revised drawings, specifications, and any addenda or clarifications that may be available.

Each change can seriously affect the construction budget, so it’s vital to ensure these are all accounted for – both in the initial bid and throughout the project.

“I have found that it is essential to establish clear communication channels with the project owner, architect or engineer. This proactive approach helps prevent misunderstandings and ensures that everyone is working from the most up-to-date information.”

Danny Mitchell, Archdesk Head of Content and former Construction Estimator

Revise, revise and revise again

A key mistake that contractors often make is to assume that construction estimating is done when the bid is won.

This couldn’t be further from the truth. It’s important to continually update, improve and revise your estimates.

If external factors affect your budget, it’s important to be aware of what extra costs are needed and where they’re going to come from.

Use the right software

Another crucial tip here is to take advantage of software tools like Archdesk. There are several ways this helps:

- Centralised data – The right tools allow you to bring all your project information together into one place, so you’re always working off a single version of truth.

- Real-time information – There’s no point updating your estimates based on last week’s information. Software tools can be updated instantly, so you’re always working off data that’s accurate to the day.

- Industry-specific features – Generic tools aren’t designed for construction– there are simply too many unique variables. Tools like Archdesk are built by and for the industry, with a deep understanding of how estimating works and the variables that affect them. This makes estimating quicker, easier and more accurate.

“Another solution I have employed is using collaborative project management software, such as Archdesk.

“These tools centralise and streamline the flow of project information among all stakeholders, making it easier to track changes, access the latest documents, and communicate with the project team.”

Danny Mitchell, Archdesk Head of Content and former Construction Estimator

Construction estimates: Not just a dive into the unknown

It can often seem like effective construction estimating is an exercise in barely-educated guesswork.

And no matter how much detail you go into, external factors as seemingly arbitrary as the weather can still ruin your plans.

But no matter how infuriating and unpredictable it may be, estimating in construction is one of the only things standing between your business and insolvency.

Detailed reporting, constant reviewing and the right technology can make a huge difference to your estimates, and ultimately, your profits.

If you want to find out how Archdesk helps with construction cost estimating, request a demo here.

Frequently Asked Questions (FAQs)

What are the 4 types of estimating?

There are several different types of construction estimates that companies use, including preliminary, detailed, quantity cost, bid cost and control cost. These generally involve varying levels of detail and are used in different stages of the bidding/project process.

What are the five main stages of an estimate?

Construction cost estimation generally involves five stages: preliminary, detailed, quantity cost, bid cost and control cost. This follows the construction project from initial feasibility checks through bidding and construction.

How do you calculate construction costs?

To calculate your construction costs, you need to add together the costs of labour, subcontractors, materials, tools, overheads and your profit margin. The more detail you go into, the more accurate your estimates will be.