Construction Tips, News & Best Practices

How to Reduce Overhead Costs in Construction in 2023

Tl;dr: Having the right tech really helps. Find out more about the best tools for construction accounting.

As a contractor, you’ll generally have multiple ongoing projects, in different places – each with its own materials, workforce and equipment. Some costs will belong clearly to one project, while others might be shared between multiple.

So where do you start?

What are overhead costs in construction?

Just like anything in the world of construction accounting, reducing your overhead costs can be a minefield.

To get to the bottom of this conundrum, it’s important first to understand what overhead costs are – and what they aren’t.

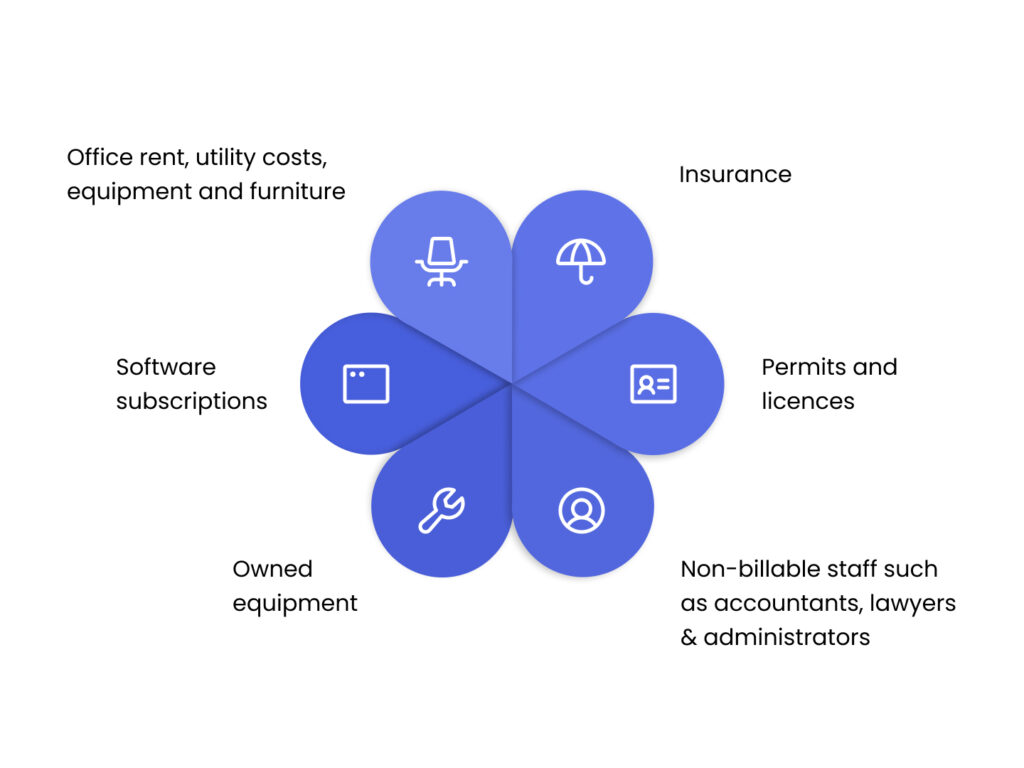

Put simply, overheads (or indirect costs) are any expenses that can’t be assigned (and thus, billed) to a particular construction project. These might include:

- Office rent, utility costs, equipment and furniture

- Software subscriptions

- Non-billable staff such as accountants, lawyers & administrators

- Insurance

- Permits and licenses

- Owned equipment

In short, overheads are any indirect costs needed for the day-to-day running of your construction business. Crucially, this doesn’t include project-specific costs such as:

- Labour or contractors

- Construction materials

- Rented equipment

Check out our recent blog on construction job costing to find out more about overheads.

Some construction companies will include job costs as overheads – but most prefer to separate billable from non-billable costs. That’s because job costs can be directly billed to a client, while overhead costs are trickier to calculate.

Why is reducing overheads so important?

“Overhead is something that never seems to go down unless you have a catastrophic event like The Great Recession and people have to make big cuts.”

Wade Carpenter, Carpenter & Company, CTAs

It’s very easy for overhead costs to gradually creep up without you noticing – particularly if your profit is going up at the same time.

And as construction industry professional Wade Carpenter explains, very few construction businesses actively monitor and reduce their costs during the good times.

If the contracts are rolling in and the bottom line is healthy – it’s easy to let overheads become a problem for another day.

But here’s the issue, when that day comes it may well be too late.

“A lot of my client base was decimated during The Great Recession. The ones that I remember that survived were the ones that kept their overheads low.”

Wade Carpenter, Carpenter & Company, CTAs

Keeping overheads low is a vital way of staying flexible and agile – which makes a huge difference in challenging times.

And with the economy looking increasingly uncertain, it’s more important than ever for contractors to start reducing costs.

But where do you start?

How high are your overhead costs?

To reduce your overhead costs, you first need to understand them. By far the best way to do that is to calculate as a percentage of your revenue.

The key question to ask yourself here is “Are my overhead costs rising faster than my profits?”

If the contracts are rolling in, you’re reporting headline profits and the business is doing well – it’s easy to let overheads increase.

Time to invest, you might think. Perhaps a snazzy new office, some new professional admin and legal staff or updated equipment.

That’s all well and good and there are plenty of sensible reasons to invest in all these things.

But if in doing so, your overheads jump from e.g. 15% to 25% of your overall revenue, you could be left in a tricky position – even if your headline profits still increase.

So how do you know if your overheads are increasing? The trick is to calculate over a long period of time – years, rather than weeks or months.

Look at your profit and loss statements over the last five years and if you’re finding that your expenses are rising (as a percentage) over that period, you might need to reduce overhead costs. So how exactly do you do that?

How to reduce your construction overhead costs

So you’ve separated your overheads from your job costs and worked them out as a percentage of revenue.

Here’s the not-quite-million-dollar question: How do you reduce construction overhead expenses?

Here are some tips to get you started.

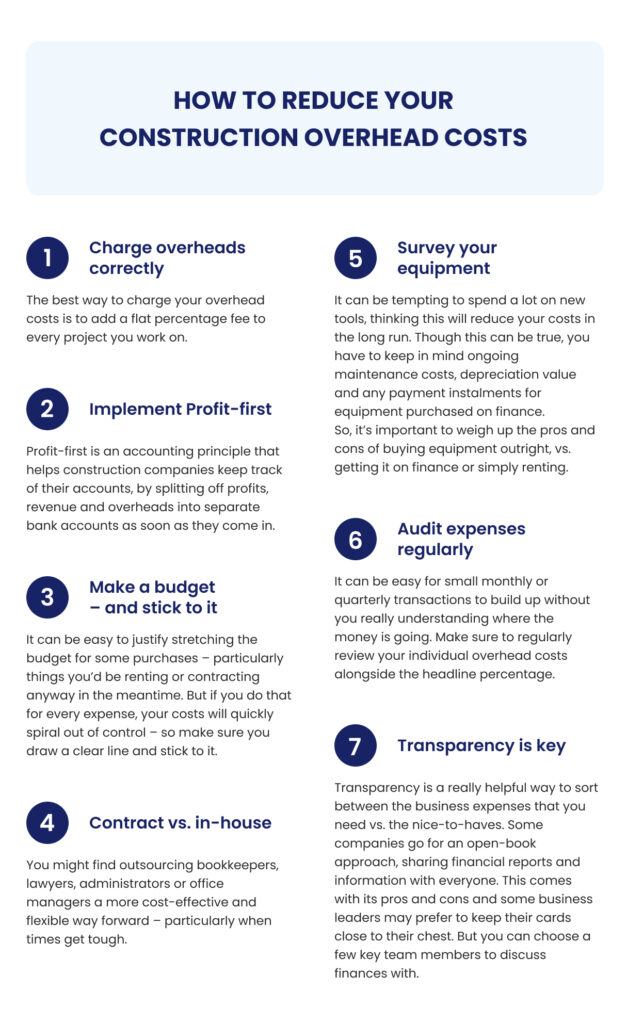

- Charge overheads correctly

Though not strictly a way to reduce your overhead expenses – this is an important way to understand and manage them.

By far the best way to charge your overhead costs is to add a flat percentage fee to every project you work on.

Many businesses don’t do this – which means overheads ultimately end up eating into profit margins.

- implement Profit-first

Profit-first is an accounting principle that helps construction companies keep track of their accounts, by splitting off profits, revenue and overheads into separate bank accounts as soon as they come in.

Rather than having one big pool of unorganised funds, this makes it much easier to know exactly how much overhead capital you have to work with.

- Make a budget – and stick to it

Once you’ve ring fenced an overhead budget, it’s much easier to stick to.

The trick here is to exercise discipline. It can be easy to justify stretching the budget for some purchases – particularly things you’d be renting or contracting anyway in the meantime.

But if you do that for every expense, your costs will quickly spiral out of control – so make sure you draw a clear line and stick to it.

“Things make sense when you look at them on an individual basis. You can justify 20 things, and each one of them may make sense individually. But getting all 20 doesn’t add up.”

Rob Williams, Profit Strategist, Iron Gate.

- Contract vs. in-house

When it comes to administrative staff, one key consideration is whether to employ or outsource.

Of course, there are many good reasons to do either.

But you might find outsourcing bookkeepers, lawyers, administrators or office managers a more cost-effective and flexible way forward – particularly when times get tough.

- Survey your equipment

Just like with employed vs. contracted labour, it’s important to constantly weigh up whether to buy or rent your equipment.

It can be tempting to spend a lot on new tools, thinking this will reduce your costs in the long run.

Though this can be true (depending on the price of renting), you have to keep in mind ongoing maintenance costs, depreciation value and any payment instalments for equipment purchased on finance.

Crucially, having outstanding debts on new equipment can be a challenge in an economic downturn.

Because you’ll still be expected to meet those repayments even if your work dries up.

So, it’s important to weigh up the pros and cons of buying equipment outright, vs. getting it on finance or simply renting.

- Audit expenses regularly

Another key tip here is to keep an eye on any regular transactions coming out of your accounts.

It can be easy for small monthly or quarterly transactions to build up without you really understanding where the money is going.

Make sure to regularly review your individual overhead costs alongside the headline percentage.

- Transparency is key

Transparency is a really helpful way to sort between the business expenses that you need vs. the nice-to-haves.

Some companies go for an open-book approach, sharing financial reports and information with everyone.

This comes with its pros and cons and some business leaders may prefer to keep their cards close to their chest.

But you can choose a few key team members to discuss finances with.

A helpful acid test is if you’re struggling to justify the expenses – there’s a good chance you don’t need them after all.

Getting to grips with construction industry overheads

Like anything in the world of construction finance, managing overheads can be a confusing and challenging process.

But if you want to keep your business in the black and your profit margins up – it’s a really important habit to get into. And that habit is much easier with the right tools.

Specialist accounting tools like Archdesk help you define budgets, forecast, monitor ongoing job costs and much more.

Check out our specialist budgeting features to find out how you can track, optimise and improve your costs.

If you want to learn more about how Archdesk can help boost your profits, request a demo today.

Frequently Asked Questions (FAQs)

- How to reduce overhead costs in construction

To reduce overheads, implement Profit-first, make an overhead budget and consider using contracted labour or rented equipment to reduce costs and improve flexibility.

- What causes an increase in overhead costs?

Overheads increase when operating expenses rise faster than your revenue. This can be easy to do if profits are increasing, but can leave you in a vulnerable position in an economic downturn.

- What does reduced building overhead costs mean?

'Reduced building overhead costs' refers to the process of cutting your non-billable expenses. This can include office rent & equipment, software licences, insurance or permits that don't belong to specific construction projects.

Danny Mitchell

Head of Content Marketing

You might also like

February 29, 2024 • 7 min read

Utilizing the human-first approach to construction projects to drive higher results.

July 3, 2023 • 6 min read

8 Best Construction Drawing Management Software (2023): A Comprehensive Guide

Find all the information you need about the construction drawing management software tools available on ...June 14, 2023 • 6 min read

The 11 Best PlanGrid Alternatives (2023)

Looking for a great alternative to PlanGrid software? Check out the 11 best construction software tools ...June 14, 2023 • 4 min read

How to win at CIS 340 and make taxes a breeze

CIS 340 is a legal obligation for contractors. But getting it right isn’t straightforward. Want ...